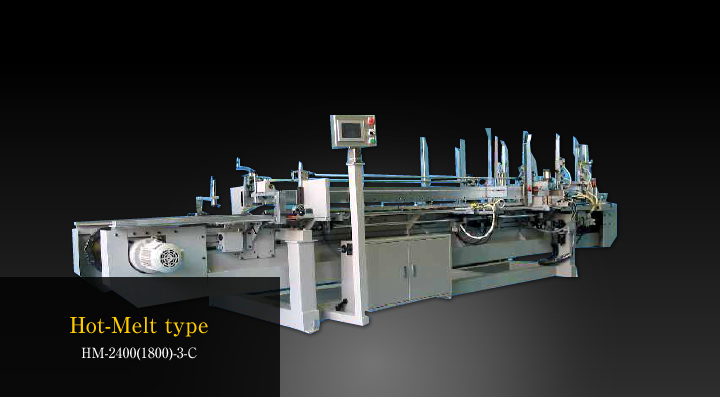

| Model | HM-2400(1800)-3-C | |

|---|---|---|

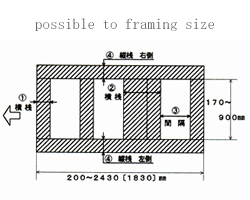

| Frame Size | Length | 200mm~2430mm (200mm~1830mm) |

| Inner width/ thickness | Inner width 170mm~900mm・thickness 8mm~50mm | |

| Capacity | 8 stations | Frames shorter than 1200mm (900mm)→16 (18) pieces/min |

| 4 stations | Frames longer than 1200mm (900mm)→8 (9) pieces/min | |

| Glue tank | Robotex (hose-less, Direct Jet)・one per side | |

| Glue(Hot-Melt) | Ever-Grip. Normally #57/ other types available for other purposes. | |

| Speed | Gears with inverters 8~28m/min | |

| Voltage/Air capacity | 5Kw/3φ・200V / 400NL/min | |

| Installation size | Width 2000mm × Length 5600(5000)mm × Height 1600mm | |

| Weight | 2900(2700)kg | |

Hopper Sizes

| ① | Rail A feeding | Up to 20~100mm |

|---|---|---|

| Rail B feeding | Up to 20~60mm | |

| Rail C feeding | Up to 20~60mm | |

| ② | Rail AB feeding simultaneous-drop | Up to 90mm |

| ③ | AB feeding minimum distance | Up to 80mm |

| C feeding minimum distance | Up to 40mm | |

| ④ | Rail: left | Up to 20~120mm |

| Rail: right | Up to 20~100mm |

1.Hot-Melt (glue)→For a smooth frame surface, and level panel.

2.To prevent blade-chipping, no metal is used.

3.Stile-holding device→For a smooth frame without bumps(exclusive feature!)

4.Direct Jet Hot-Melt gun style→No hose=no clogging, maintenance and trouble-free(exclusive feature!)

5.With Dog-Setting device→The chains can be set digitally without using the sample frames, faster and more accurate dog setting (up to 64 frame data can be stored, dog inserted manually).

6.Rail-feeding device→With A,B, and C-three different kinds of hoppers.

1.Stock-hopper device for A, B →Insert and store 10 times or more of rails/ stiles.

2.Exit-Surface Tucker device→Braces the corners of large frames with staples.

3.Other options: various sizes of the machines, etc.