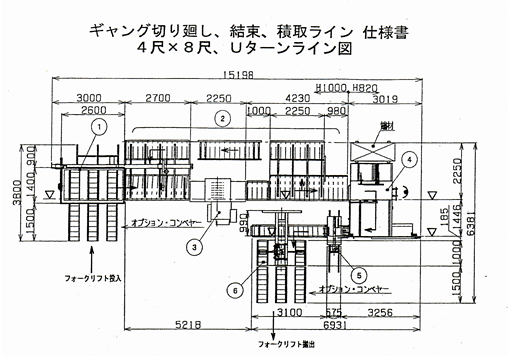

■machine description

| ① | Raw Material Inserter | HGS-2400-4/height →up to 1200mm |

|---|---|---|

| Inserter Table-lifter | Width 1200mm×Length 2400mm×Height 350mm×3tons | |

| Standby Conveyer | 2 sets : on the table-lifter and the entry-part, 1500mm length | |

| ② | Vertical Cut-Off Conveyer | HGR-2400-4-Pile |

| Setting for insertion numbers | From 1to 3 pieces、continuous cuts. Counter setting | |

| 2枚重ね投入装置 | 昇降移動ハサミ装置・揃えストッパー装置付 | |

| ③ | Gang-ripper | Use width 450mm~600mm gang |

| ④ | 重ね分離送り装置 | HSBR-2400-2 段差を利用して重ね、クロス送り、分離送りする。 スピードアップの為、クロス送りは2系統を設置する 結束機への送りは、1結束幅を金具で分離、送り込む。 |

| ⑤ | End-Binding device | Model→HBC-2400-1 Auto-packing→Nichiro Kougyou, corp・SX-500 model |

| ⑥ | Bound-material Loader | 型式→HRT-2400-3-結束 ブロワー式吸着、上下移動自動積取とする |

| Loading Table lifter | Width1000mm×Length 2000mm×Height 300mm×2tons | |

| Sending Conveye | テーブルリフター上と出口部1500mm長さと2セット付とする |

■Main specifications of the line

| 1 | Possible Process Material Size | 3尺×6尺~4尺×8尺迄とし、中間サイズも可能 |

|---|---|---|

| Possible Insert Material Siz | On the table-lifter: up to width 1200mm× length 2450mm×height 1200mm | |

| Possible Load Material Size | On the table-lifter: up to width 950mm×lengths2450mm× height 1200mm | |

| 2 | Thickness of the material | Min 8mm~Max 60mm |

| 3 | Size of the bind | Up to Width 120mm~250mm× Height 80mm~150mm |

| 4 | Direct Operator | Align/pile and material waste process→1person |

| 5 | Specs of the Gang | Use Gang with : width 450mm~600mm Capacity→900mm×1800mm×15 tons、about 1500 pieces/day |

| 6 | The Binder | Nichiro Kougou, Corp・SX-500(PP band-width16mm) |

| 7 | Height of the line | Vertical Cut-Off→1000mm/Piling・Loading→820mm |

| 8 | All the sizes can be changed after detailed design | |

※Power consumption-17KW、3phases (without Gang)

※Air Consumption-1070N liter/Min、 more than 5kg/c㎡

※Pit Size- width 1400mm×length 2600mm×depth 700mm(approx)

From 1200mm× 2400mm Line to 1200mm×4200mm Line

40m3/day ・1 person

One-person operation

Pile-Cutting for high efficiency.

Fast set-change with various types.

Cross-Cut machine→ Can be operated at a safe distance from the blades.

Cross-Cut machine→ Can be operated at a safe distance from the blades.

Can be connected to an inkjet printer.

Can be connected to an inkjet printer.

Connect with gang-line, molder-line, and running-saw for labor-saving.

Connect with gang-line, molder-line, and running-saw for labor-saving.